The Packaging and Packaging Waste Regulation (PPWR) was adopted earlier this year and firmly sets out the future of packaging across the entire EU. But that’s good news…

Under the new Regulation, all packaging on the European market must be recyclable by 2030. And that is just one of several key goals that will determine how — and if — a product can be placed on the EU market at all.

Ambitious? Absolutely. But the real question for manufacturers is not only what the Regulation demands, but how to actually comply — without improvisation, and without sacrificing product quality or brand recognition.

It is estimated that nearly half of the industry is still studying the Regulation and trying to interpret the rules. A quarter of producers have already started their first serious packaging audit: what can be replaced, and what needs to be redesigned? Still, the vast majority are far from real change — understandably so, as many details still need to be defined through implementing acts.

THE BIGGEST CHALLENGE – INTERPRETING THE REGULATION

More than half of companies say the biggest challenge is interpreting PPWR requirements and the lack of clear guidelines. Next comes the unavoidable dilemma: which materials are truly suitable in practice, and which just look “green” on paper? Costs and limited resources are also significant factors, as everything must fit into realistic budgets and timelines.

Interestingly, the thing that arguably should be the top concern currently causes the least worry: will consumers accept the new, more sustainable packaging? Experience shows that if the customer doesn’t “buy” the idea, the best recyclability remains just a claim on the label.

Solutions exist, but they require a step-by-step approach with no room for chance.

KALIGRAF: PPWR IS NOT A REASON FOR PANIC, BUT AN OPPORTUNITY FOR OPTIMIZATION AND PROGRESS

Design for recycling is increasingly seen as the first step in any sustainable packaging strategy.

Kaligraf, a Zagreb-based studio that has been providing prepress services and managing packaging production for leading domestic, regional, and even some global brands for over 30 years, has continued to grow by embracing the new expertise and practices demanded by PPWR.

In its integrated consulting and operational packaging development process, Kaligraf works on the principle that, under the new regulatory framework, improvisation is not an option. Design for recycling is the key.

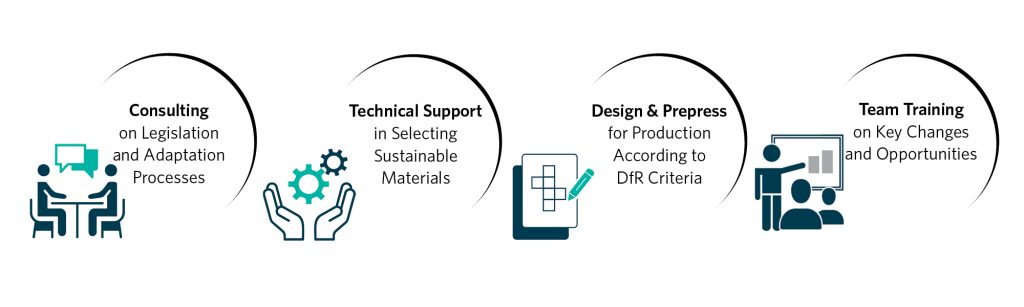

Kaligraf Consulting not only advises on regulatory compliance, but also provides systematic support through every phase of packaging development — from the initial concept and design adaptation, to print file preparation and quality control.

We can recycle tomorrow, but we must design for recycling today.

- Do we know what our packaging is made of, and can it actually be recycled in practice?

- Do we have an accurate inventory of all formats and materials?

- Who is interpreting PPWR for us and leading the project?

- Will customers accept the changes?

- Do we have a plan and budget – and can we meet the deadlines?